GPS MACHINE CONTROL MODELING

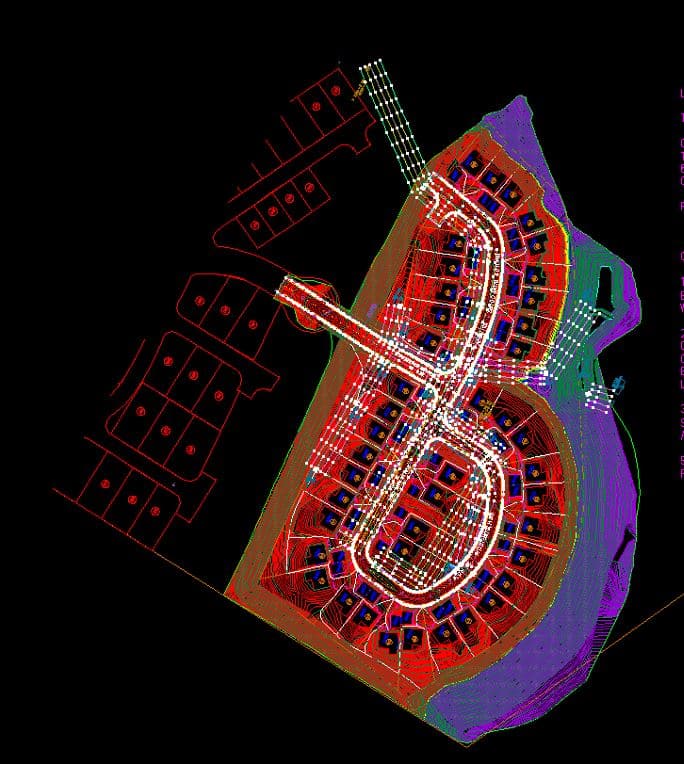

Our team at Take-Off Professionals provides comprehensive GPS modeling and 3D machine control modeling services for all your earthmoving needs. From transforming CAD files to creating precise machine control models and converting paper plans, we ensure your projects are equipped with the tools they need to succeed.

3D and GPS Machine Control Modeling Services

The benefits of machine control systems are what make this breakthrough in earthwork machinery so popular. When carried out correctly — in conjunction with high-quality 3D machine control models — it typically provides the following advantages:

- Increases heavy-duty machine efficiency and productivity.

- Decreases operating expenses such as fuel, repair and maintenance costs.

- Reduces raw materials costs by using them more effectively.

- Lowers surveying costs by eliminating ongoing grade checking.

- Reduces labor costs by increasing individual worker efficiency.

Of course, for any machine control systems project to be successful, the 3D machine control model it’s working off must be accurate and complete. That’s why more and more construction companies are turning to 3D machine control modeling services — like those we provide at TOPS — to bid on, accept and complete more projects with confidence and proficiency.

Call us at 623-323-8441 to speak directly with a member of our team.

Request A Free Quote

The Role of GPS Machine Control in Modern Construction

While the productivity of construction sites was once largely dependent on surveyed stakes and skilled equipment operators, the evolution to GPS machine control systems is forging a new standard for worksite efficiency. GPS machine control consists of instruments that provide machine operators with data on equipment positioning, like bucket and blade positioning and desired grades. Common devices include lasers, sonic equipment, total stations, and particularly advanced 3D machine control technology.

Machine control models are driven by signals from GPS modeling and GNSS, which are similar to those used in consumer devices but tailored for construction operations. Technology in machine control modeling utilizes on-site base stations to contrast signal data, ensuring equipment operates in tandem with the prepared 3D model machine control plans for precise grading.

Enhanced precision from GPS machine control modeling and base stations allows in-field machines to execute tasks at exact coordinates efficiently, minimizing manual stake placements, and saving valuable resources.

Ready to discuss your project?

Applications of GPS Modeling in Heavy Machinery Operation

Sensor technology has paralleled advances in vehicle safety, and similarly, GPS modeling technology has ushered in marked improvements across a range of heavy machinery. The adoption of 3D model machine control is on track to become an industry norm, with numerous manufacturers pre-wiring equipment for this technology.

Applications of 3D machine control modeling include:

Paving:

Utilizing machine control models for automated steering and planning enhances precision in paving procedures.

Dozing:

Implementing 3D machine control modeling augments site safety and enables precise dozing, grading, and scraping.

Excavating:

Machine control modeling services support excavators in maintaining correct positional relations for consistent digging accuracy.

Delivering Precision with In-House Expertise at TOPS

Three Simple Steps to Begin Your Project

To get started with TOPS, you just need to follow three easy steps:

Step 1: CAD Files

Provide the CAD files for the project in formats like AutoCAD .DXF and .DWG, among others. Files can be uploaded to their FTP site or shipped with the paper plans.

Step 2: Paper Plans

If sending paper plans, they will scan and store them electronically. You can transmit the scans or ship the paper plans.

Step 3: Work Order

Fill out a data prep work order on their website with the details of your scope of work. TOPS can accommodate various needs; just specify how you want the job to look.

We have no association with any manufacturer or system type but provide 3D models for all manufacturers

The TOPS Advantage in GPS Machine Control Modeling

With over two decades of expertise in delivering GPS machine control modeling, our commitment to accuracy and detail is evident in our strong performance record. Annually creating approximately 1,000 high-quality machine control models, we strive for exceptional turnaround times and unwavering client support.

Beyond our skillful team and proven success in 3D machine control modeling, we strive to make your experience seamless. Our custom platform, developed for secure and straightforward client data submissions, underscores that working with TOPS is efficient, enabling you to continue focusing on your business while we expertly handle your GPS machine control modeling needs.